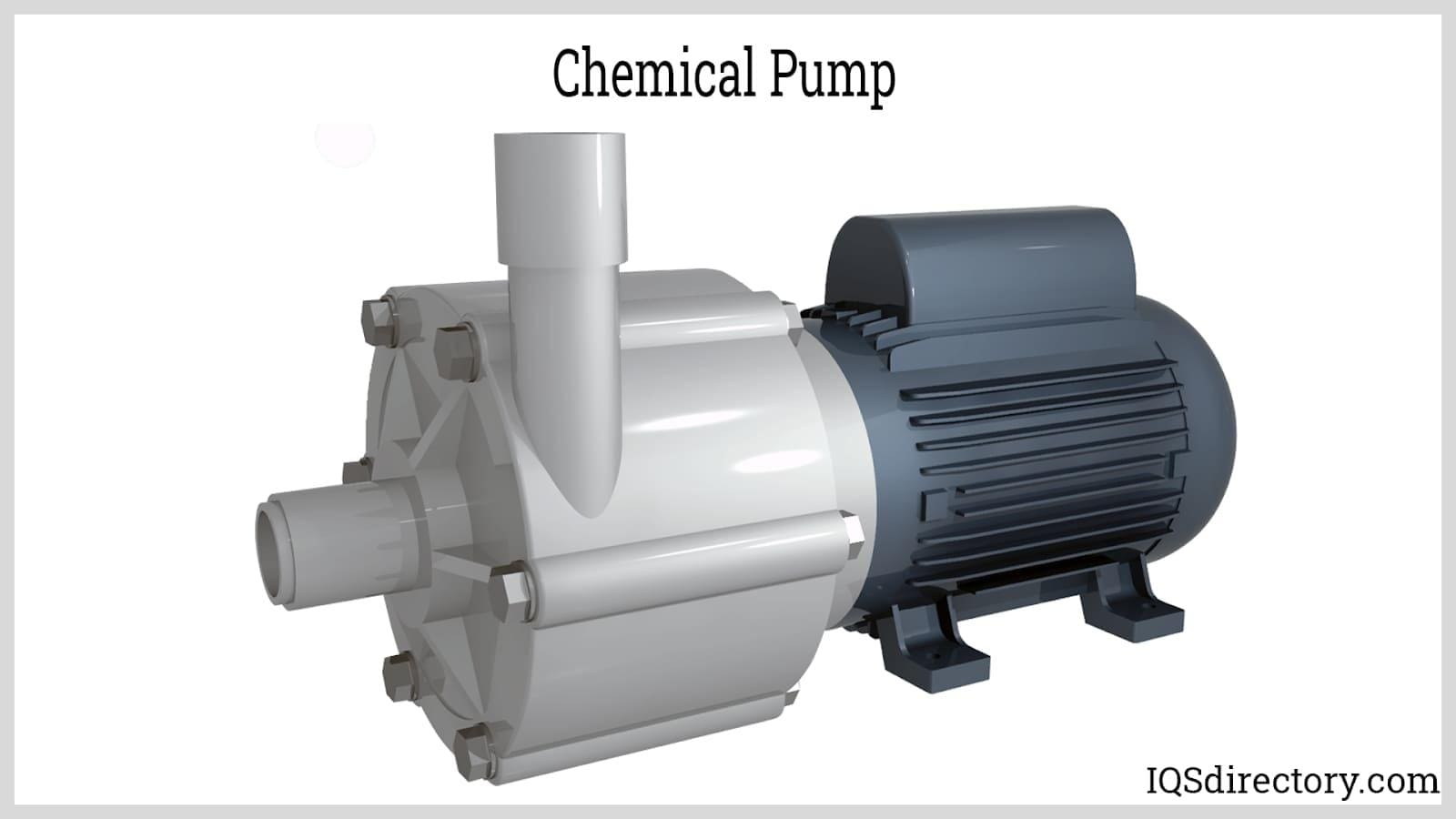

Chemical pumps are designed to deal with hazardous, corrosive compounds. They contain corrosion-resistant materials. Manufacturers use chemical pumps to process bleach, acid, resin, commercial or industrial abrasives, and corrosive liquids. In a chemical centrifugal pump, rotating impellers push the liquid to specific speeds. Centrifugal force in the pump produces the liquid’s velocity. When the amount of flow is more than the required pressure, chemical pumps are used for chemicals with viscosities similar to water. Read More…

When it comes to moving your hard-to-handle liquids quickly and efficiently, John Blue’s centrifugal transfer and spray pumps are second to none. John Blue Company’s product lines include centrifugal spray pumps, cast iron centrifugal pumps, and polypropylene centrifugal pumps.

Hydra-Tech can help handle your most difficult jobs, and its centrifugal pumps are able to handle high viscosity liquids like refinery waste, molasses, latex & crude oil. Hydra-Tech can make standard pumps as well as custom design them to fit your needs and offers the widest variety of models in a variety of materials. Hydra-Tech is CE Certified and can help find or design the right pump for you.

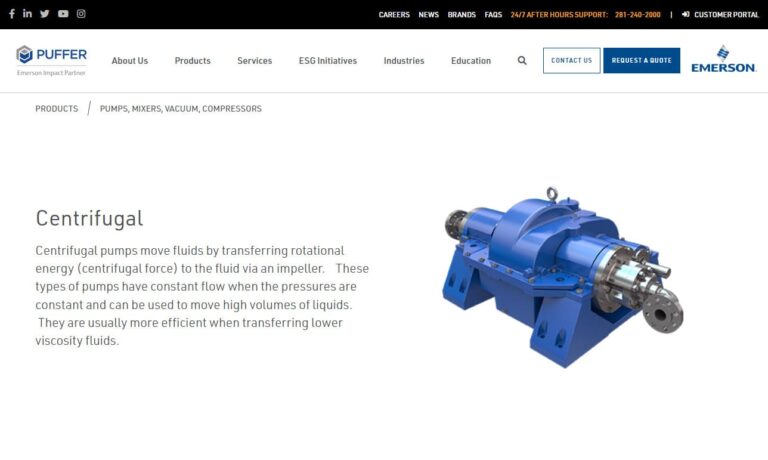

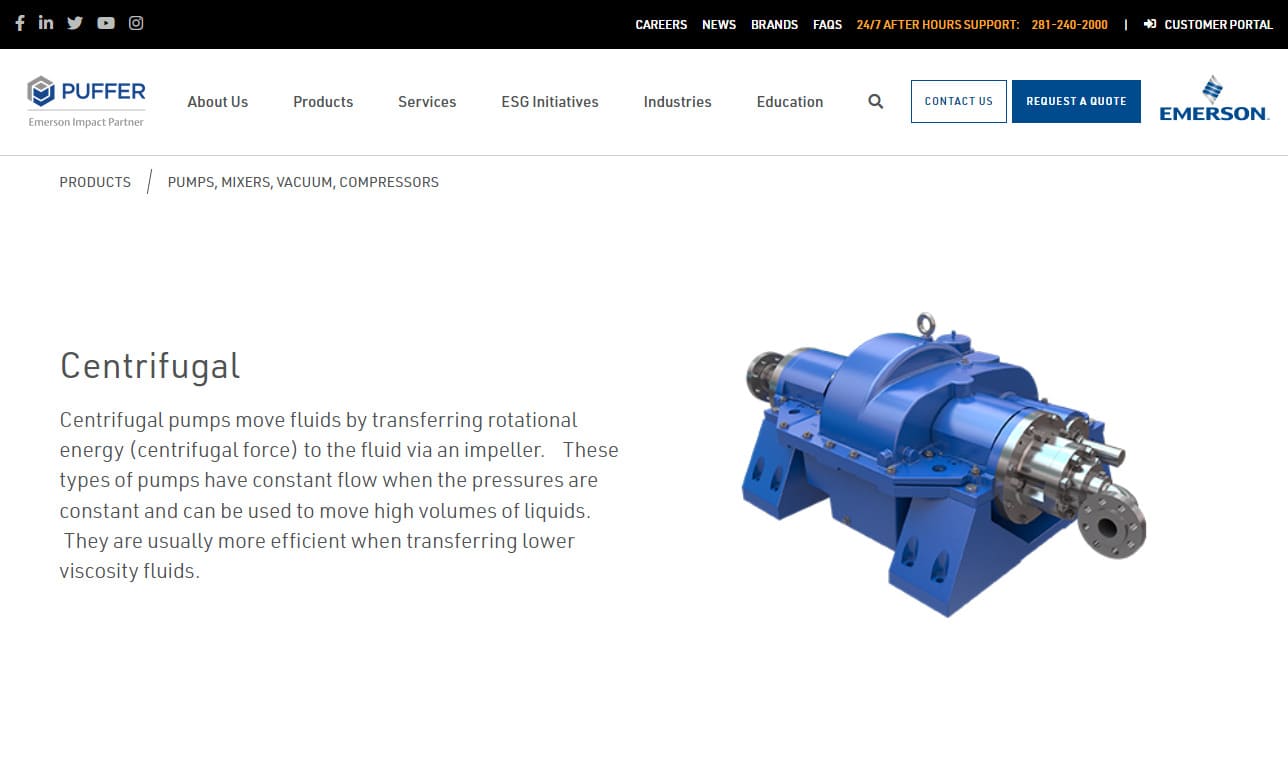

Puffer Sweiven Rotating Equipment offers a wide range of centrifugal pumps from a number of quality manufacturers. We offer these durable products in horizontal, vertical and submersible designs.

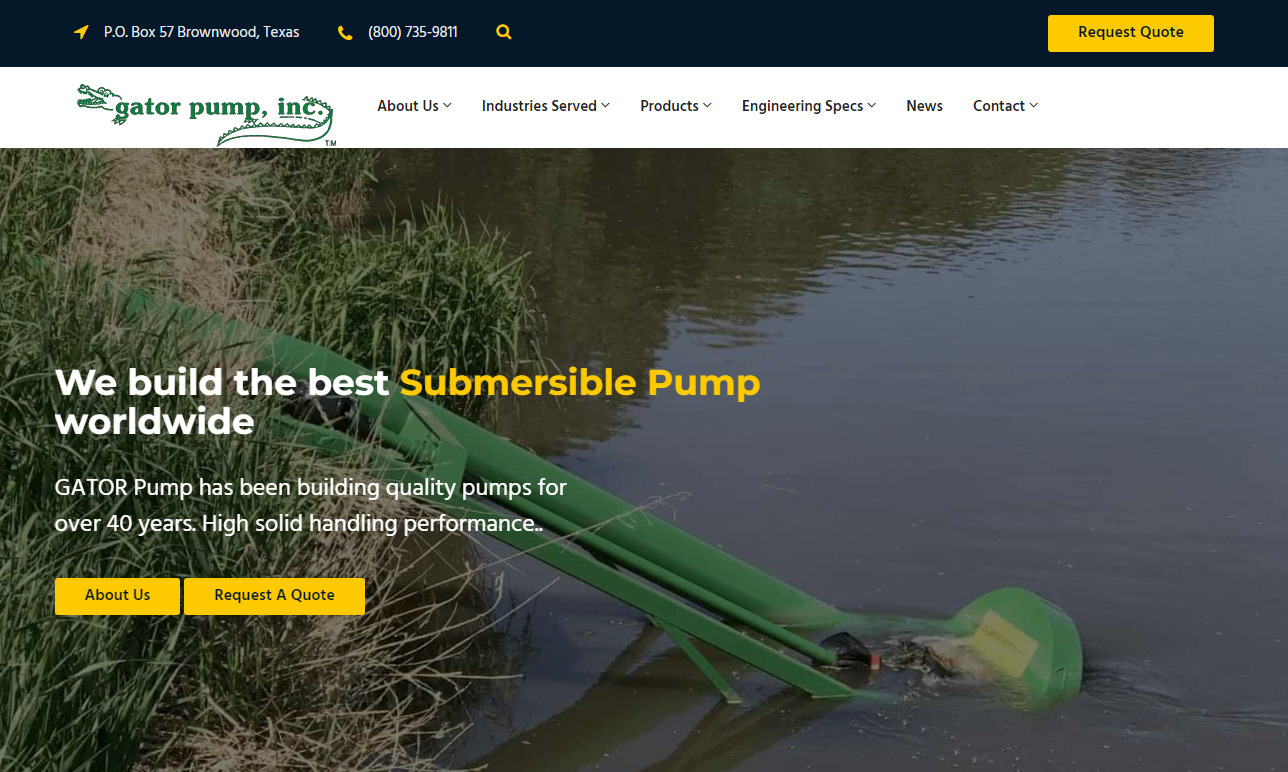

Since 1978, our radial flow centrifugal pumps have been used for flood irrigation, flood control, liquid waste pumping, & more. Our trailer centrifugal pumps supply water with either 540 or 1000 RPM PTO drive. Our sump pumps “attack” your pumping problem using tractor, diesel or electric power. For more information on our centrifugal pumps give us a call today, we are ready to help!

Texas Process Equipment supplies specialty pumps, such as centrifugal pumps and other process equipment. TPE offers products from Chempump, Barnes Pumps, Isochem, Micropump, Price Pump and more. Through a common sense approach to business, communication and information technology, TPE offers the lowest "total cost of ownership" to its customers. Call today to see what TPE can do for you.

More Chemical Pump Manufacturers

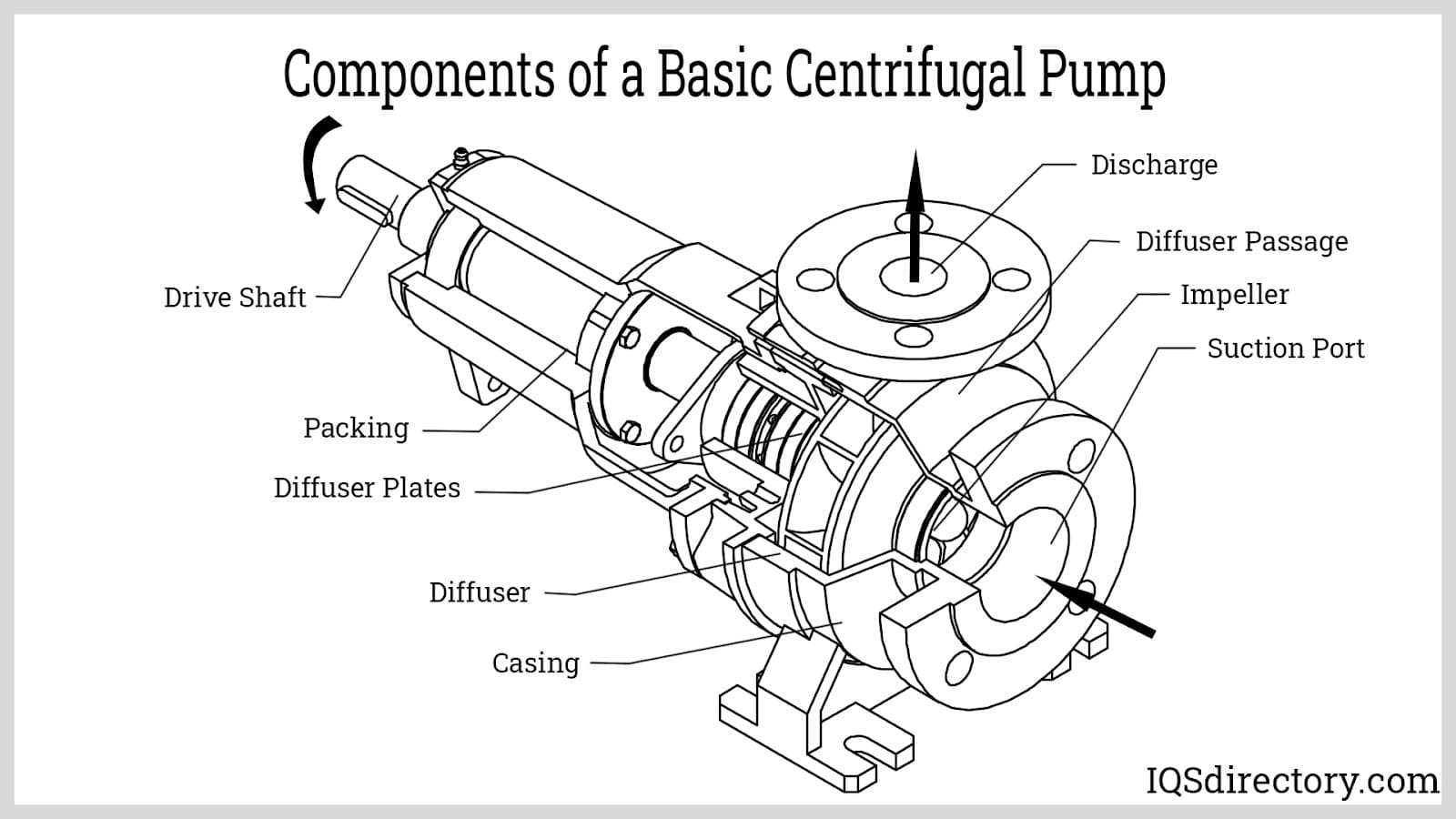

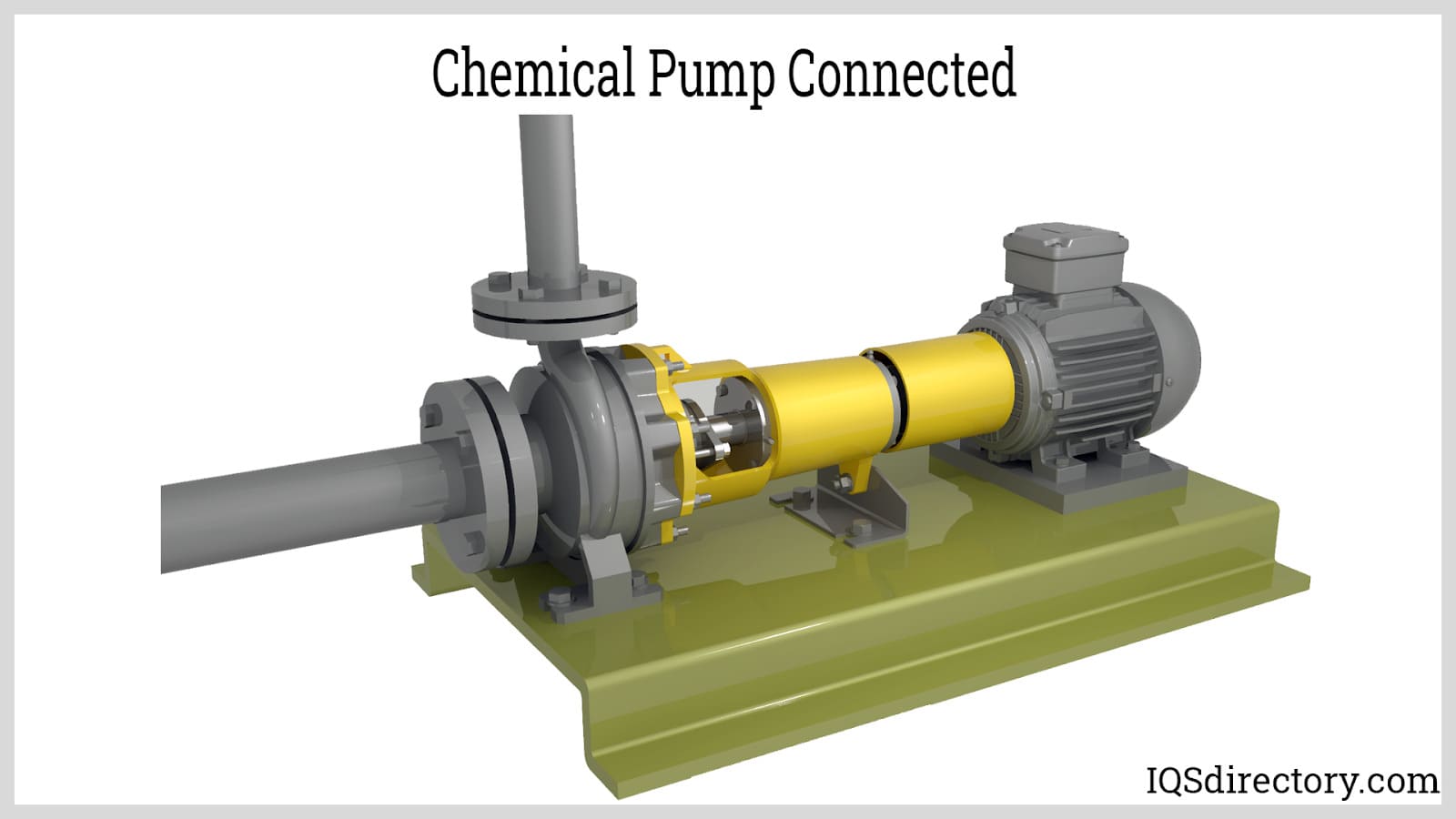

A normal pump may become brittle, dissolve, swell, leak or fail when working with chemicals. Chemical pumps are made with special consideration, from the materials it’s made from to the concentration and temperature of the fluid it processes. Every centrifugal pump comprises mechanical parts that enable the pump to function. A basic centrifugal pump includes a sealing mechanism, a shaft, an impeller, a delivery pipe, a casing, and a suction pipe.

Working Principle of a Chemical Pump

A chemical centrifugal pump has an internal rotating impeller. This impeller links to the motor through an aperture in the pump housing. The aperture has a mechanical seal to prevent leaks. The seal is made of ceramic, silicon carbide, or carbon rings. While the pump shaft spins, one ring rotates while the other stays motionless. As a result, a small amount of fluid circulates between these two seal faces as it passes through the pump to lubricate them.

Before operating, liquid should fill the pump. When the pump is turned on, the impeller begins rotating. The blades rotate the liquid. Centrifugal force causes the liquid to spray out and away from the impeller due to centrifugal force. The liquid is injected into the pump casing’s diffusion chamber at slower and slower speeds. As a reaction, the pressure progressively builds. The liquid is now agitated in the vane's center, so neither air nor liquid can produce a vacuum depression. Air pressure forces the liquid in the pump through the suction pipe. It is drained and continuously sucked out of the cistern.

Selecting a Chemical Pump

When selecting a chemical centrifugal pump, manufacturers should consider the characteristics of the chemicals they’re using. Knowing the chemical’s temperature, pH value, density, viscosity, and particle contaminants is important. This information helps narrow down what material and seal will work best on the pump. If you don’t ensure the chemical pump you purchase can handle the specific chemicals used, it will delay production and increase expenses.

Advantages of a Centrifugal Chemical Pump

Corrosive Resistance

Corrosion-resistant materials are used to construct centrifugal chemical pumps. These pumps are built to endure the harshest chemicals, enabling chemical manufacturers to move a wide range of fluids under multiple circumstances. Chemical pumps are long-lasting, offering an increasing return on investment.

Reliable

Chemical centrifugal pumps are a solid option for reliable pumps. They have withstood time because of their robust designs. These pumps deliver dependable, durable performance.

Energy Efficiency

Centrifugal chemical pumps are rated favorably in energy efficiency compared to other pumping systems. Their effectiveness lowers per-unit and short-term life-cycle expenses. This is crucial when numerous pumps and other machinery must run concurrently.

Easy to Maintain

Fortunately, centrifugal chemical pumps require little routine maintenance. In addition, their straightforward, effective construction reduces the number of parts that require maintenance or repair. Their low-maintenance design lowers repair costs and downtime.

Choosing the Correct Chemical Pumps Company

To make sure you have the most productive outcome when purchasing Chemical Pumps from a Chemical Pumps Supplier, it is important to compare at least 5 or 6 Manufacturers using our list of Chemical Pumps suppliers. Each Chemical Pumps Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Chemical Pumps company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Chemical Pumps companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services