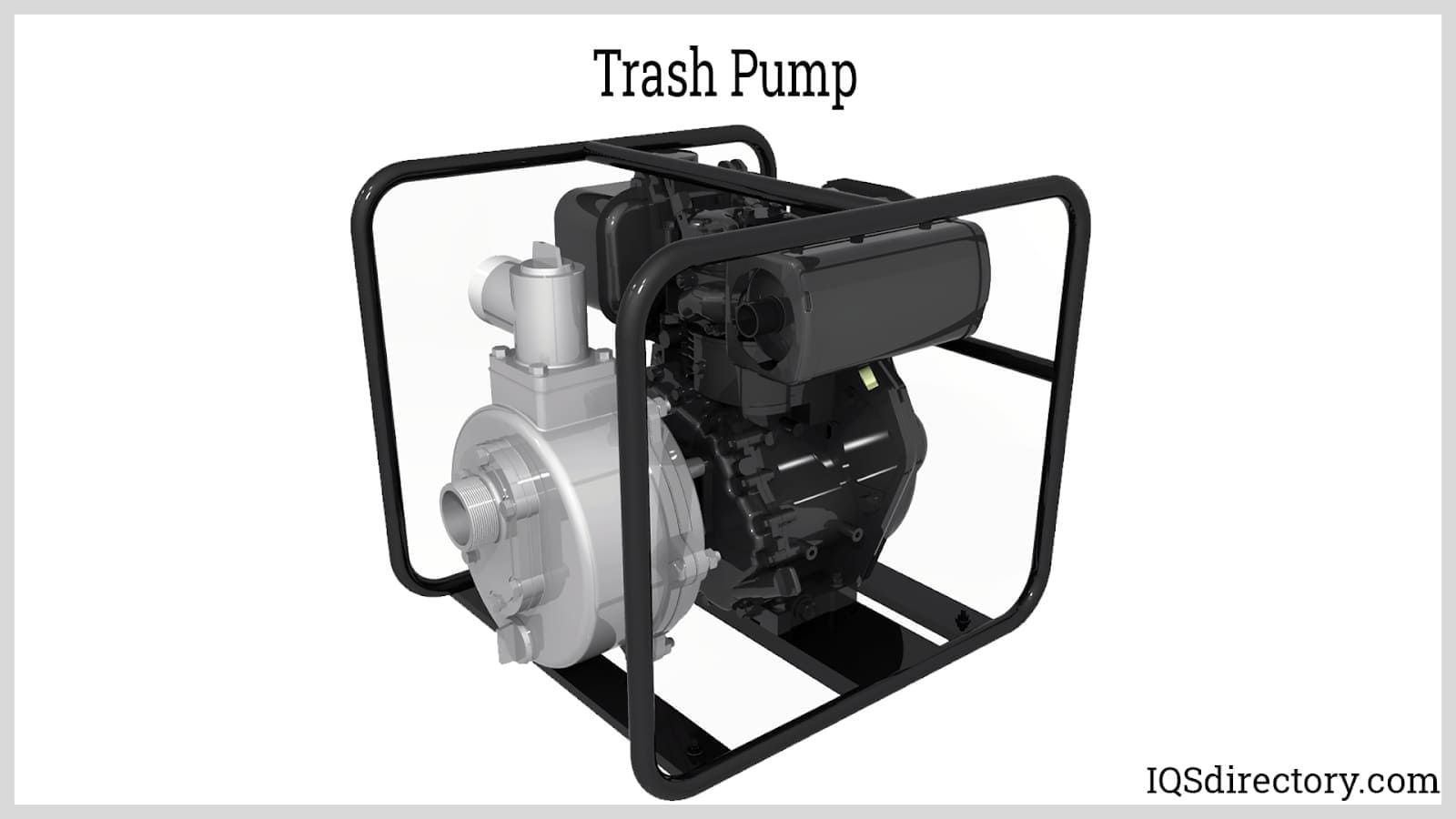

Trash pumps are portable pumps that are typically used for applications requiring the removal of large volumes of water, including soft and hard materials, mud, leaves, twigs, sand, and sludge. Most trash pumps are robust, portable centrifugal pumps with wider discharge openings and deeper impeller vanes than other pumps. Trash pumps can move hundreds, if not thousands, of gallons per minute and can process materials that have some suspended particulates that can clog other centrifugal pumps. Read More…

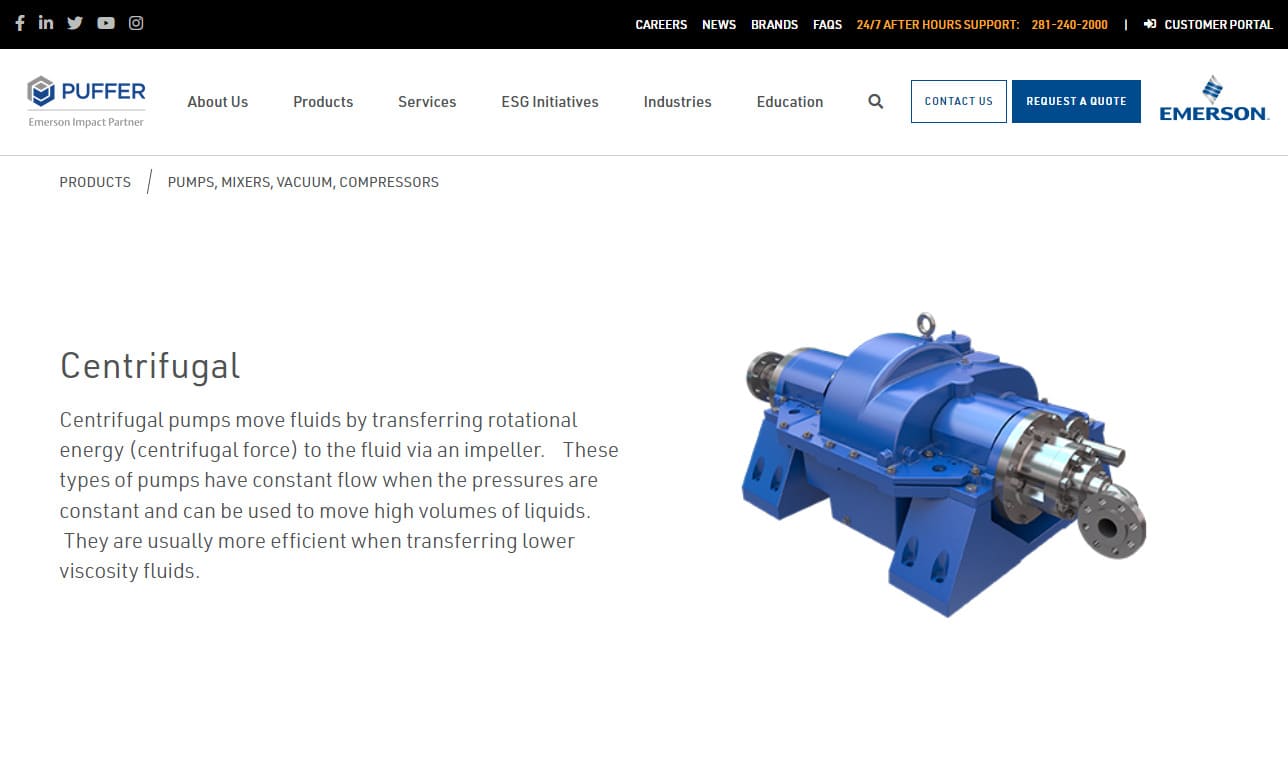

When it comes to moving your hard-to-handle liquids quickly and efficiently, John Blue’s centrifugal transfer and spray pumps are second to none. John Blue Company’s product lines include centrifugal spray pumps, cast iron centrifugal pumps, and polypropylene centrifugal pumps.

Hydra-Tech can help handle your most difficult jobs, and its centrifugal pumps are able to handle high viscosity liquids like refinery waste, molasses, latex & crude oil. Hydra-Tech can make standard pumps as well as custom design them to fit your needs and offers the widest variety of models in a variety of materials. Hydra-Tech is CE Certified and can help find or design the right pump for you.

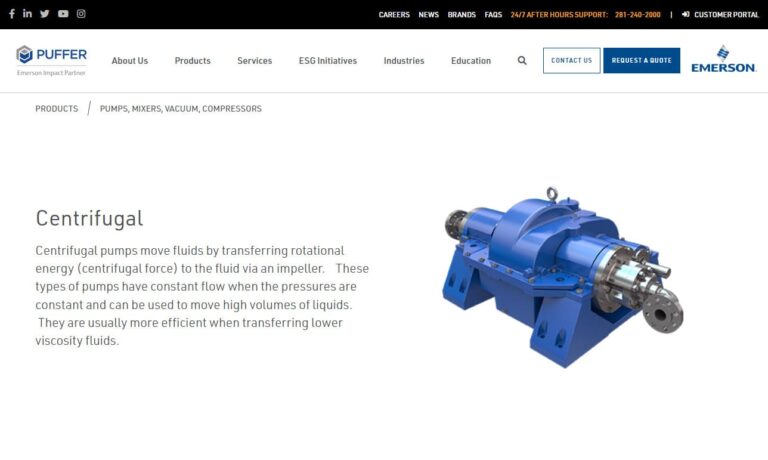

Puffer Sweiven Rotating Equipment offers a wide range of centrifugal pumps from a number of quality manufacturers. We offer these durable products in horizontal, vertical and submersible designs.

Since 1978, our radial flow centrifugal pumps have been used for flood irrigation, flood control, liquid waste pumping, & more. Our trailer centrifugal pumps supply water with either 540 or 1000 RPM PTO drive. Our sump pumps “attack” your pumping problem using tractor, diesel or electric power. For more information on our centrifugal pumps give us a call today, we are ready to help!

Texas Process Equipment supplies specialty pumps, such as centrifugal pumps and other process equipment. TPE offers products from Chempump, Barnes Pumps, Isochem, Micropump, Price Pump and more. Through a common sense approach to business, communication and information technology, TPE offers the lowest "total cost of ownership" to its customers. Call today to see what TPE can do for you.

More Trash Pump Manufacturers

The trash pump does not grind the materials that it receives. Cast iron, aluminum, steel, and stainless steel are all possible materials used to construct trash pumps. Trash pumps use a big inlet and strong power to pick up debris while delivering maximum pressure and discharge flow. A trash pump can be powered by alternating electricity, direct current, compressed air, gas, diesel, or solar energy.

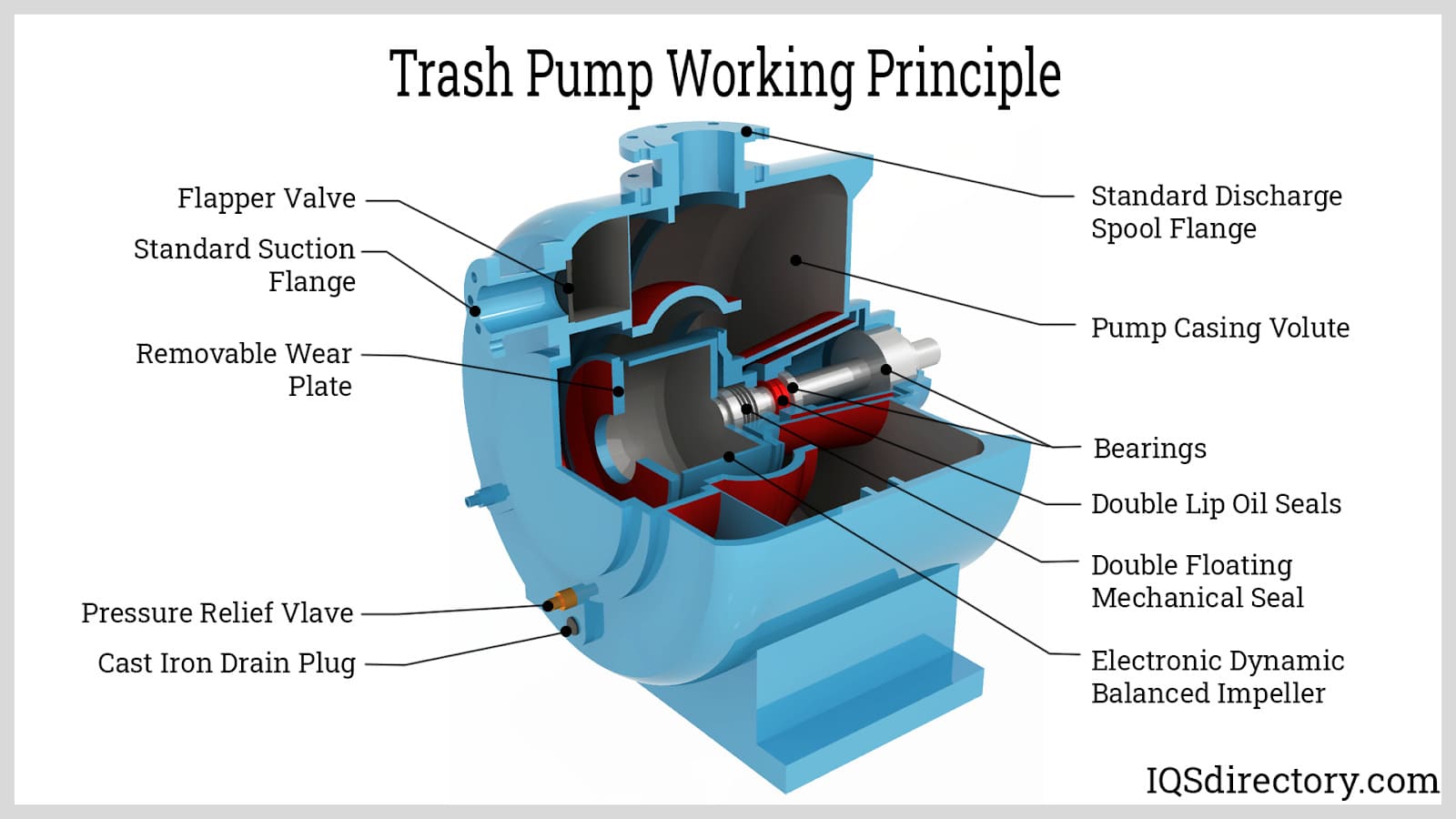

Trash Pump Working Principle

A trash pump draws contaminated water in and filters it before discharging it from the other end. This separation technique is performed differently depending on the type of pump. Centrifugal trash pumps are the most commonly utilized trash pump worldwide due to their portability and excellent efficiency.

When a trash pump is operating, contaminated water is sucked in. By creating a low-pressure space inside the pump cavity, the pump sucks in the fluid. A trash pump’s impeller generates the water's kinetic energy. Water is moved axially and radially by the impeller blades' centrifugal force. To further compress the water, the filtered water is directed into the volute casing while the debris and other solid particles are transported toward the pump’s central hub.

The speed is converted into pressure energy via the volute case. This power aids in processing the fluid through the pump. A trash pump should be switched when water stops moving through a pipe. A trash pump should not be used to pump gasoline, caustic chemicals, or other fuels due to the damage these materials can have on the pump. Safety and mechanical issues could result from this process.

It is important to check the water’s temperature when using a trash pump. High-temperature water can cause cavitation issues (where static pressure forms pockets of vapor-filled cavities in a liquid), boil when pulled in, harm the pump's impeller, and have a high vapor pressure.

Major Features of Trash Pumps

Trash pumps have special capabilities that enable them to move enormous volumes of liquids that are heavily contaminated with particles and rubbish. These abilities are a result of their components; some of these components are discussed below.

Impeller

Trash pumps utilize an impeller, a revolving part of a centrifugal pump, which helps limit clogging. The impeller raises the liquid's pressure and flow by accelerating fluids away from the rotor. The fluid's increased pressure and flow decrease the likelihood of clogging. An impeller does not grind down the garbage and other debris; they are propelled out whole. The fibrous materials, solids, and grit are directed through the pump without grinding because of the liquid vortex the impeller generates in the casing.

Strainer

A pump may become clogged if materials enter that are greater than the pump’s capacity. Strainers are installed at the inlet of trash pumps to stop debris and other materials from entering which are larger than the pump's volume. It is also essential to make sure the strainer is always submerged for it to perform its job.

Self-Primer

Trash pumps self-prime. The priming process is performed in order to remove air and vapor from the pump and the suction line. The priming procedure entails pushing air out of the pump and replacing it with fluid, such as water. No pumping will occur if priming is not performed. A self-primer guarantees that there is always liquid in the priming chamber. If fluid levels need to be raised before starting an engine, a switch will be activated to indicate that manual priming must be performed.

Types of Trash Pumps

Although trash pumps all serve the same general purpose, variations exist to better serve specific applications. We examine a few trash pump varieties below.

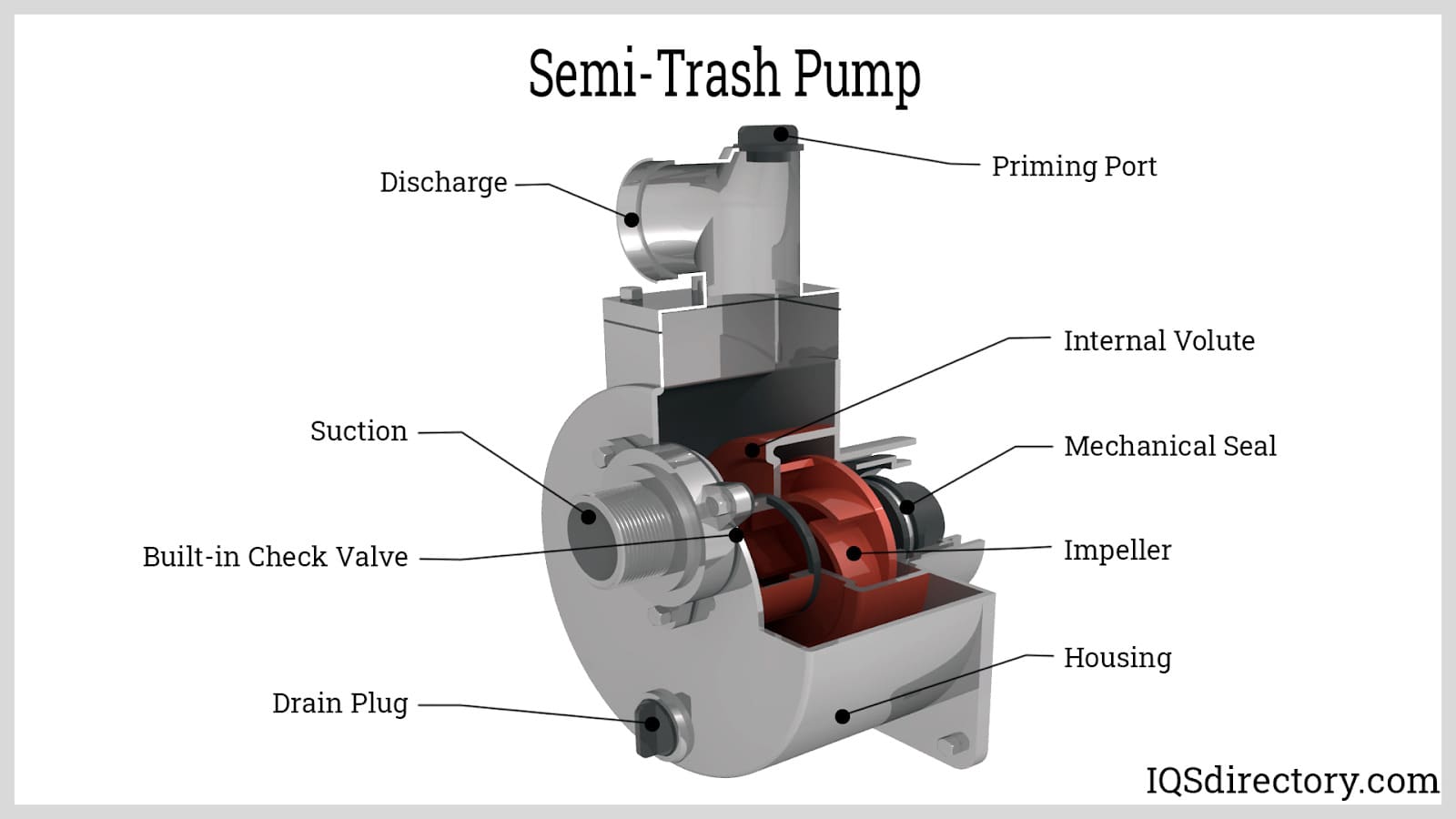

Semi-Trash Pumps

Semi-trash pumps are pumps featuring smaller openings. Therefore, semi-trash pumps are not intended for use with large solids or high concentrations of solid material. Regular trash pumps are better suited for applications that need vigorous water pumping or for heavily-solidified slurries.

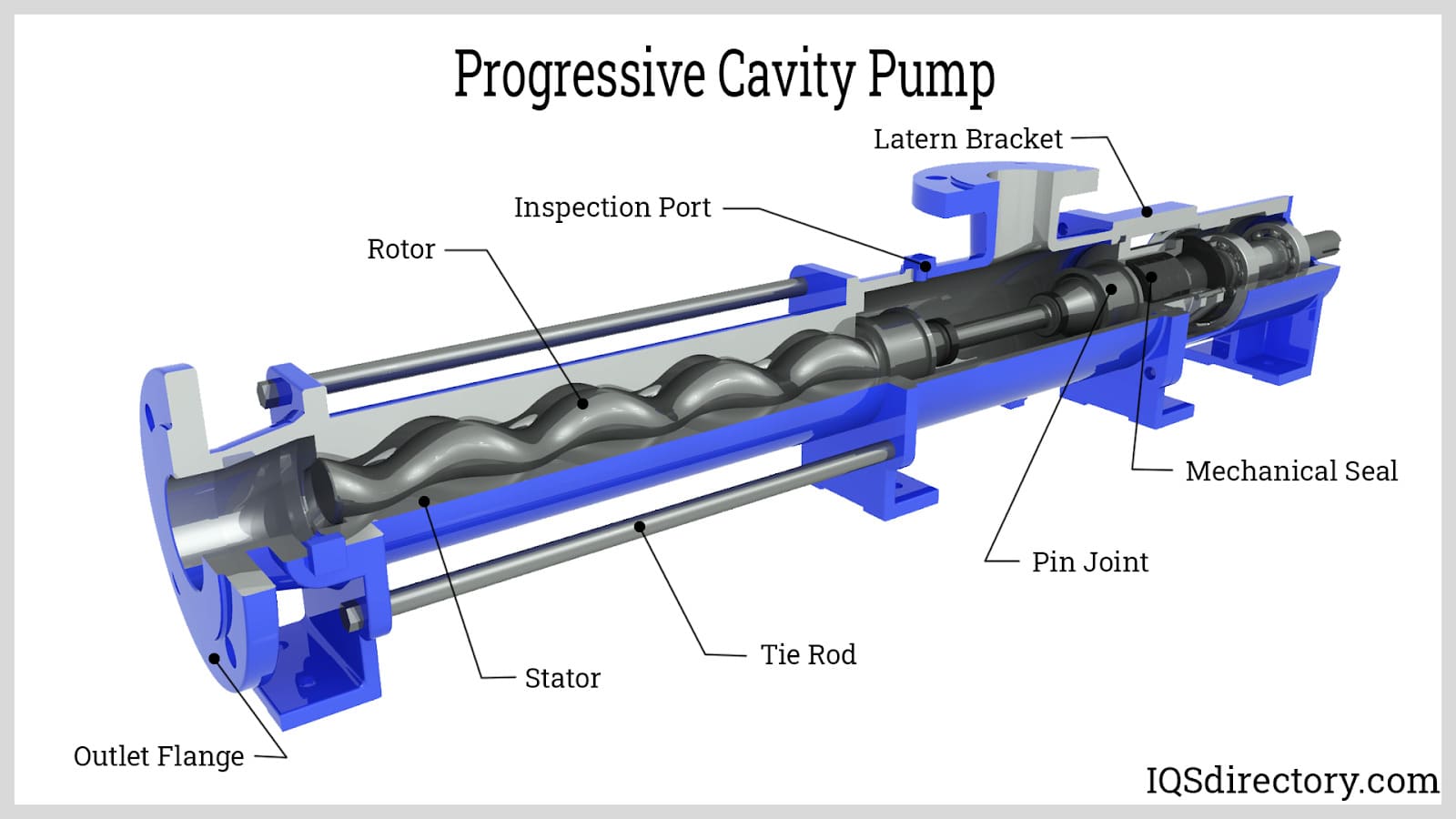

Progressive Cavity Pumps

A progressive cavity pump moves slurries and liquids with suspended materials. The liquid enters the storage tank after flowing from the pump's delivery side to its suction side. These pumps effectively move highly- viscous, slowly-moving materials while allowing the liquid to flow continuously from them. Progressive cavity pumps are relatively simple to clean and, as a result, are used in situations requiring greater hygienic standards.

Positive Displacement Pumps

Positive displacement pumps move fluids through pistons, gears, diaphragms, and other components. A vacuum is produced when a fluid enters their fixed chamber and is pumped out. This vacuum is also useful for moving objects. Displacement pumps work well when pumping viscous liquids under high pressure.

Syringe Pumps

Syringe pumps handle materials that need precise flow rates at precise times. The two types of syringe pumps are infusion pumps, which process fluid under tightly-controlled pressures, and withdrawal pumps, which are used to remove fluids.

Choosing the Proper Trash Pumps Manufacturer

To make sure you have the most constructive outcome when purchasing Trash Pumps from a Trash Pumps Company, it is important to compare at least 4 Companies using our list of Trash Pumps manufacturers. Each Trash Pumps Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Trash Pumps business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Trash Pumps companies with the same message.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services