Centrifugal pumps are unique and important members of the industrial world. The purpose of a centrifugal pump is to move fluid in a controllable fashion by engaging the fluid with strong rotational kinetic energy. This rotational energy increases the pressure of a fluid during the pumping process. While centrifugal pumps are sometimes used to raise liquid levels, they are most often used to induce a pressurized liquid flow. Read More…

When it comes to moving your hard-to-handle liquids quickly and efficiently, John Blue’s centrifugal transfer and spray pumps are second to none. John Blue Company’s product lines include centrifugal spray pumps, cast iron centrifugal pumps, and polypropylene centrifugal pumps.

Hydra-Tech can help handle your most difficult jobs, and its centrifugal pumps are able to handle high viscosity liquids like refinery waste, molasses, latex & crude oil. Hydra-Tech can make standard pumps as well as custom design them to fit your needs and offers the widest variety of models in a variety of materials. Hydra-Tech is CE Certified and can help find or design the right pump for you.

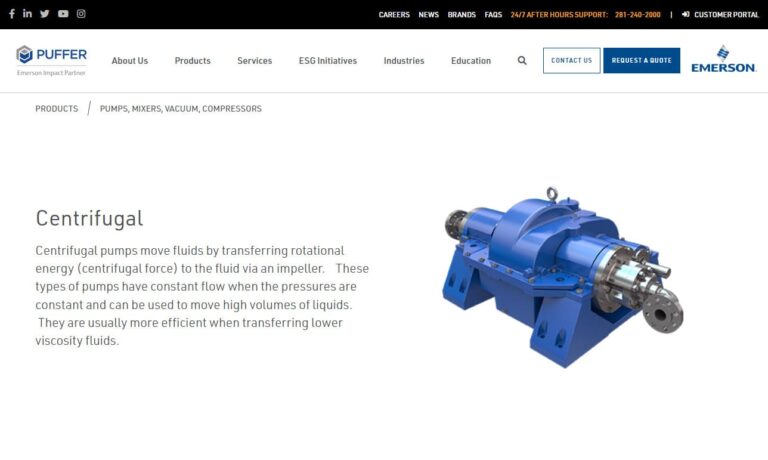

Puffer Sweiven Rotating Equipment offers a wide range of centrifugal pumps from a number of quality manufacturers. We offer these durable products in horizontal, vertical and submersible designs.

Since 1978, our radial flow centrifugal pumps have been used for flood irrigation, flood control, liquid waste pumping, & more. Our trailer centrifugal pumps supply water with either 540 or 1000 RPM PTO drive. Our sump pumps “attack” your pumping problem using tractor, diesel or electric power. For more information on our centrifugal pumps give us a call today, we are ready to help!

Texas Process Equipment supplies specialty pumps, such as centrifugal pumps and other process equipment. TPE offers products from Chempump, Barnes Pumps, Isochem, Micropump, Price Pump and more. Through a common sense approach to business, communication and information technology, TPE offers the lowest "total cost of ownership" to its customers. Call today to see what TPE can do for you.

More Centrifugal Pump Manufacturers

Centrifugal pumps are classified as members of the rotary machine family among industrial devices.Centrifugal pumps are mechanical devices used to transport fluids by converting rotational energy from an impeller into kinetic energy. They are widely utilized in various industries for fluid transfer, circulation, and pressure generation.

History

Although centrifugal pumps came into existence near the start of the modern era, they have only recently become widespread in the industrial world. Despite their invention in Europe (during the late seventeenth century) and later migration to the U.S. (in the early nineteenth century), centrifugal pumps were overshadowed for decades by the use of positive displacement machines. The key factor in the adoption of centrifugal pumps occurred in the earlier part of the twentieth century with the development of high speed technology (e.g. high speed electric motors, steam turbines, etc.) that made centrifugal pumps a more practical choice than they had previously been. For approximately seventy-five years, centrifugal pumps have been widely used across many different industries in the light of this (relatively recent) technological change.

Materials

Most centrifugal pumps are built with cast iron or other metals like aluminum. These types of materials are used because they can withstand harsh chemicals and conditions that would eventually destroy other materials. The materials used to construct a centrifugal pump plays an important role in its overall efficiency. As centrifugal pumps have increased in popularity, pumping research and development have expanded the range of materials used to construct them. Strong metals with high levels of corrosion resistance are still the material of choice for centrifugal pumps. However, more and more manufacturers now use materials such as fluorocarbons and thermoplastics for seals and other various pump parts.

Parts

Although centrifugal pumps are highly useful and vary widely in type, they are characterized by a remarkable degree of simplicity in their basic design. The three basic components of a centrifugal pump are the impeller, the casing (usually a volute), and the pumping unit (or mechanical assembly).

The impeller is the “signature” feature of the centrifugal pump since it is responsible for producing rotary energy and velocity. The center of the impeller is also known as its eye or hub. The impeller possesses at least one or multiple vanes which extend outward from its center. It should be noted that impellers can vary widely in diameter and produce different degrees of rotational speed.

The pumping unit (or mechanical assembly) simply refers to the combination of other pump components that enable the impeller to be rotated. Minimally, this section of the overall pump houses an actual pump (which is stationary) along with some type of driver. The impeller is fixed to the rotating shaft of the driver in order to be turned. (While the most common type of driver is an electric motor, other types of drivers such as natural gas engines or steam turbines are sometimes used.) Other components in the pumping unit include bearings to support the driver shaft, sealing mechanisms to prevent fluid leakage, various structural elements designed to help the pump withstand different loads or stresses, and wear surfaces for pump repair.

All of the previously described parts are encased in a casing. (Since the most common type of casing is the volute, this term is sometimes used interchangeably with casing.) This casing does far more than simply provide protection for the inner components of the pump. In fact, it is responsible for converting the rotational energy produced by the impeller into a defined liquid flow.

How It Works

The actual operation of a centrifugal pump is also marked by a surprising degree of simplicity. As the shaft within a centrifugal pump rotates, the attached impeller turns with it. At the same time, the pump within the pumping unit directs fluid to the center (or eye) of the spinning impeller. The impeller’s motion transfers a high amount of kinetic energy to the fluid as it enters from the pump. This interaction, in turn, causes the fluid to work through to the tips of the impeller vanes. Eventually, liquid is rapidly discharged from the impeller (at its furthest diameter) and driven to the pump’s casing. As high-velocity liquid from the impeller encounters resistance in the form of the pump casing, its speed gradually reduces and its pressure increases. This pressurized fluid then exits the pump through the discharge ports at the outer perimeter of the volute channels.

The design of the impeller within the casing serves to control and produce this discharge. Instead of being centrally aligned within the casing, the impeller is usually situated so that its farthest diameter lies just past the discharge port in the casing channel. This area within the centrifugal point is known as the cutwater. From the cutwater on, the gap between the impeller and casing wall widens all the way to the actual discharge point. This unique geometry enables maximum pressure within the liquid that is discharged from the impeller as it flows along the casing and toward the discharge point.

Advantages and Disadvantages

Centrifugal pumps offer numerous advantages that make them widely used in various industries and applications. Firstly, centrifugal pumps are known for their simplicity and ease of use. They have a relatively straightforward design, consisting of a rotating impeller that creates centrifugal force to move the fluid. This simplicity makes them easy to install, operate, and maintain, resulting in cost savings and reduced downtime. Secondly, centrifugal pumps are highly efficient. They can handle large flow rates and generate high discharge pressures, making them suitable for both low and high flow applications. With their efficient operation, centrifugal pumps can effectively transfer fluids over long distances and overcome elevation differences, making them versatile in diverse scenarios. Additionally, centrifugal pumps are capable of handling a wide range of fluids, including liquids with varying viscosities and abrasive particles. They can handle both clean and dirty liquids, making them suitable for applications in industries such as mining, wastewater treatment, and chemical processing. Another advantage of centrifugal pumps is their ability to operate over a wide range of operating conditions. They can be designed and configured to handle different flow rates, pressures, and temperatures, providing flexibility to meet specific requirements. Furthermore, centrifugal pumps can be interconnected in parallel or series to enhance performance and provide redundancy, ensuring continuous operation even if one pump fails. Centrifugal pumps are also generally more compact and lighter compared to other types of pumps, allowing for easier installation in limited spaces. Their compact design also results in lower material and construction costs. Lastly, centrifugal pumps offer a high degree of reliability and durability. With fewer moving parts, they have fewer components prone to wear and tear, reducing the likelihood of breakdowns and maintenance requirements. This reliability translates into increased uptime, improved productivity, and reduced overall operating costs.

In summary, centrifugal pumps provide advantages such as simplicity, efficiency, versatility, wide fluid handling capabilities, adaptability to various operating conditions, compactness, and reliability. These qualities have established centrifugal pumps as a preferred choice in numerous industries, ensuring efficient fluid transfer and contributing to overall operational success.

Centrifugal pumps, despite their many advantages, do have several limitations and disadvantages. They are not well-suited for handling high-viscosity fluids, and their performance tends to decline when pumping thick or viscous substances. Cavitation is another concern, as it can lead to damage and reduced efficiency. Additionally, centrifugal pumps have limitations in handling solids or abrasive particles, which can cause wear and damage to the impeller and casing. Operating conditions, including flow rate and head pressure, significantly impact their performance, requiring careful selection and sizing. Noise and vibration generation during operation are also common drawbacks. While these disadvantages exist, understanding and considering them in the pump selection and design process can help mitigate potential issues and ensure optimal performance in specific applications.

Types and Applications

Many types of centrifugal pumps exist for different applications. A centrifugal pump can be used to transport liquids or gases such as chemicals, corrosive materials, oil, resin, acid, bleach, and more. Centrifugal pumps are commonly identified by their specific application or by the nature of one of their basic parts.

Types of Pumps by Application

A water pump is used for various water transfer applications. These pumps are versatile, lightweight, and sometimes high pressure if necessary. One of the most common types of water pumps is a sump pump. A sump pump is often used in residential settings to reduce flooding or water accumulation in a low-lying area. The pump may be combined with a pressure tank so that the water can be distributed away from its source.

Trash pumps are special centrifugal units designed to pump out large volumes of water at a rapid pace. Rather than pump pure water, trash pumps are used to pump polluted sources like sewage, sludge, and wastewater. These materials can be very thick and possess a high degree of viscosity. (Viscosity refers to a fluid’s internal friction and its resistance to flow.) Thus, a trash pump’s impeller is designed with deep veins and a large discharge to create the necessary kinetic energy to move highly viscous liquids.

A jet pump is a centrifugal pump that is aided by jets for maximum suction power. With advances in technology, centrifugal pumps continue to become more powerful and more capable of lifting heavy fluids for applications in some industries. Jet pumps in particular are becoming less popular as submersible pumps become more powerful. Submersible pumps are used underground in a place where water is almost always present. These pumps do not need to remove air from their suction line in order to provide continuous flow. Submersible pumps are designed as compact units where the motor and pump are close together so that the entire device can be lowered into a well hole. These well pumps are typically powered by a nearby electrical source.

The self-priming pump models now available on the market make startup time much faster. For applications where easy maintenance, sanitation, and gentle handling are all important, hygienic centrifugal pumps are now being used.

Types of Pumps by Parts or Design

A close-coupled end-suction pump is a centrifugal pump that possesses a close-coupled, end-suction pumping unit. It is one of the most common types of centrifugal pumps. In addition to attaching the impeller to the end of the motor shaft, these pumps mount the casing directly onto the motor’s face.

The design of a centrifugal pump can be optimized to meet the needs of particular situations. For instance, axial flow pumps are built with a vertical shaft that has an impeller attached to it perpendicularly. The purpose of this design is to push liquids upwards.

Considerations

Clearly, centrifugal pumps are versatile and useful industrial devices. Their usefulness, however, can only be maximized if certain factors are taken into account. Some of the more important factors are briefly described below.

- The kinetic energy transferred to a liquid increases with the diameter and speed of a pump’s impeller. Thus, the most straightforward way to modify a pump’s performance is to modify the impeller’s speed or diameter. Of the two options, the latter is more economical and therefore more popular. Sometimes modifications in both impeller speed and diameter are combined to achieve a specific result.

- The amount of energy needed to move liquid for a particular application depends not only on the viscosity but also on the amount of liquid that is being moved. One key term in the subject of centrifugal pumps is head, which refers to the theoretical vertical height (in feet or meters) that a liquid exiting a pump’s discharge could achieve. This theoretical measurement is sometimes known as the shut-off head since it represents a point where a pump would produce insufficient energy to move any further liquid. When selecting or using centrifugal pumps, it is wise to assess their performance in terms of head measurements and make modifications to reduce friction within the system as needed.

- Suction conditions tend to be overlooked to the regret of pump users. This term refers to the optimal conditions for a pump to perform suction; specifically, it refers to conditions where a pump can successfully create a partial vacuum in order to allow pressure to push liquid up a suction pipe into a pump. (Contrary to popular belief, liquids cannot be “pulled” up vertically since they lack tensile strength.) Suction conditions are particularly important to note in high-altitude applications where a pump’s maximum suction lift (in feet) decreases with increasing altitude.

Choosing the Right Centrifugal Pump Supplier

To ensure you have the most productive outcome when purchasing a centrifugal pump from a centrifugal pump supplier, it is important to compare several suppliers using our directory of centrifugal pump suppliers. There, each centrifugal pump supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each centrifugal pump business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple centrifugal pump companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services